Display racks is needed for every showroom and exhibition, in order to know how to choose a good display racks, it is necessary for you to know how the display racks are produced, below are our regularly production processes:

1.Blanking

We use furniture square pipes (Different from the galvanized square pipes on the market) to ensure that the seamless thickness of the superior surface of raw materials is thicker than that of galvanized square pipes, and the thickening of materials will not lead to grinding deformation.

2 Welding

Welding the display rack needs to use two processes,which is protection welding and argon-fluorine welding combined, to ensure the appearance of the display rack greatly reduce the welding point.

3. Polishing

The craftsmen have more than 10 years of experience and use advanced tools for grinding, to ensure that the grinding details are more beautiful.

4 .Pickling

There are impurities and oil on the surface of the square tube material. To ensure that the quality of the paint on the display rack, the impurities are removed by fire pickling, and the 270 degrees high temperature paint is used.

5. Assembly

To ensure that the customer can receive the qualified display rack, each set of racks will be checked for any problems after assembly. Then confirming that the racks are integrity, we will disassemble the packaging and then deliver the goods.

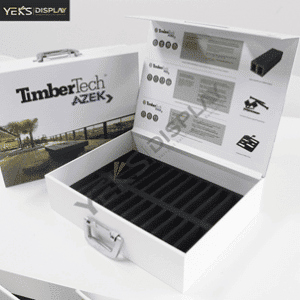

6. Packaging

The display rackis packed by the carpet or paper leather box, shipping will give customers advice on whether to do wooden pallet packaging shipping security according to the customer’s delivery address or product particularity.

The production process is transparent and open.

Welcome to visit our factory anytime! We are waiting for your coming!